From day one, Ørsted has been committed to working closely with potential local suppliers. During the construction of Greater Changhua 1 & 2a, we’ve worked with 200+ local suppliers and sub-suppliers to deliver Taiwan’s first world-class offshore wind farms and more than 7,200 direct and indirect jobs were created

Going extra miles for local supply chain cultivation

Thanks to an ambitious partnership between the Taiwanese Government and the offshore wind industry, Taiwan aims to produce more than 20 GW of offshore wind power by 2035.

Ørsted is playing a leading role in this green transformation. We are going the extra mile from investment to knowledge-sharing in order to drive a healthy growth of the industry.

In 2020, we launched the Offshore Wind Industrial Development Fund to support the ramp up of technological capabilities of local sub-suppliers with good potential and nurture local talent. Ørsted also supported the launch of a supplier portal to enable developers across the region to connect with suppliers for their renewable energy projects.

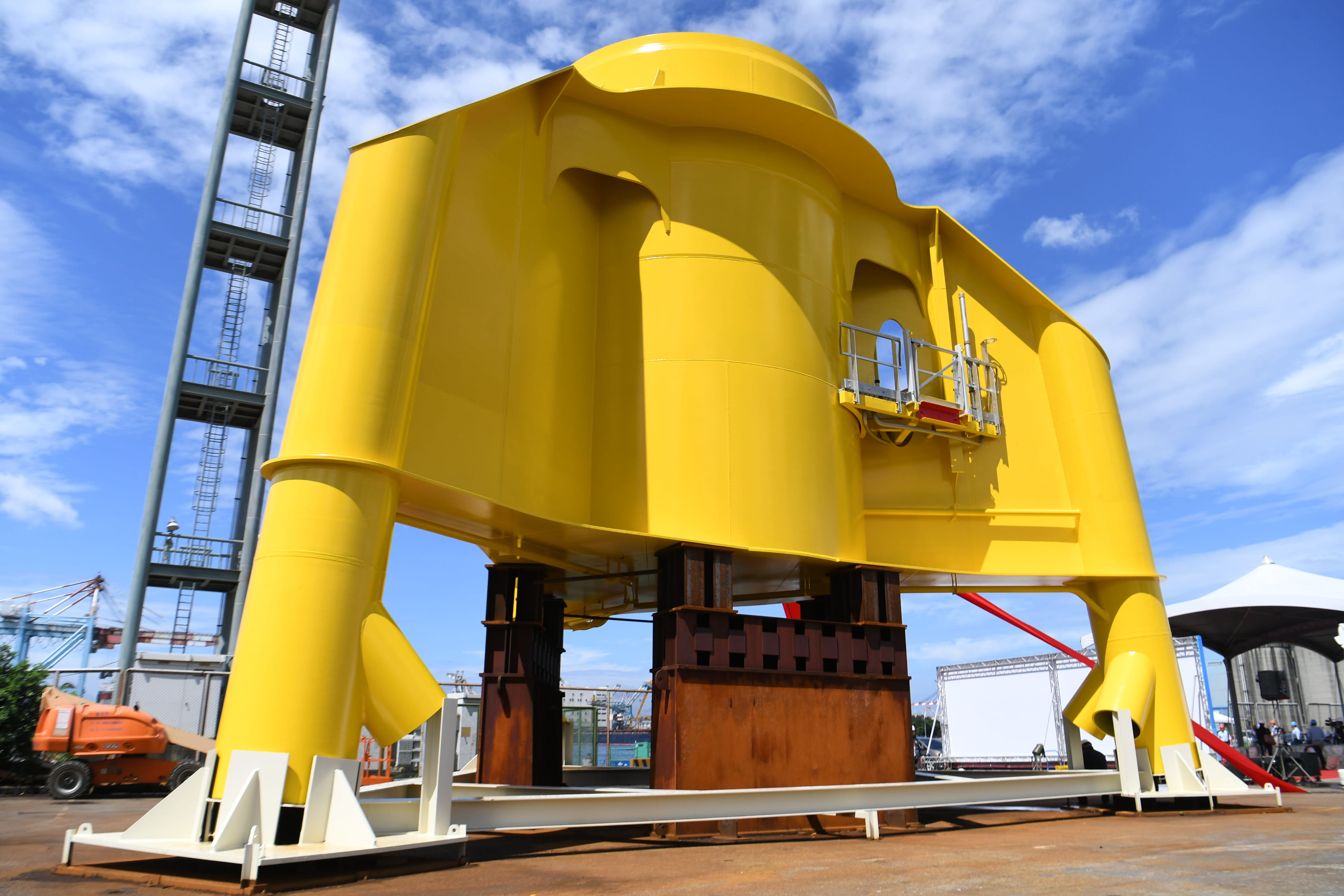

Notably, Ørsted along with Siemens Gamesa Renewable Energy (Siemens Gamesa), inaugurated a nacelle assembly facility at the Port of Taichung in September 2021, the first of its kind in the Asia-Pacific region to deliver locally assembled nacelles.

In August 2022, Ørsted inaugurated Asia-Pacific’s largest, first green-designed operations and maintenance hub at the Port of Taichung to ensure optimal performance of the wind farms and stable output of clean energy.

Innovation and new technology

Ørsted is the No.1 knowledge centre for offshore wind. We are at the forefront of innovation, R&D, technology development and cost reduction in offshore energy. We are proud to support and collaborate with innovative companies and research organisations in renewable energy and the industries of the future.

Here are some examples: